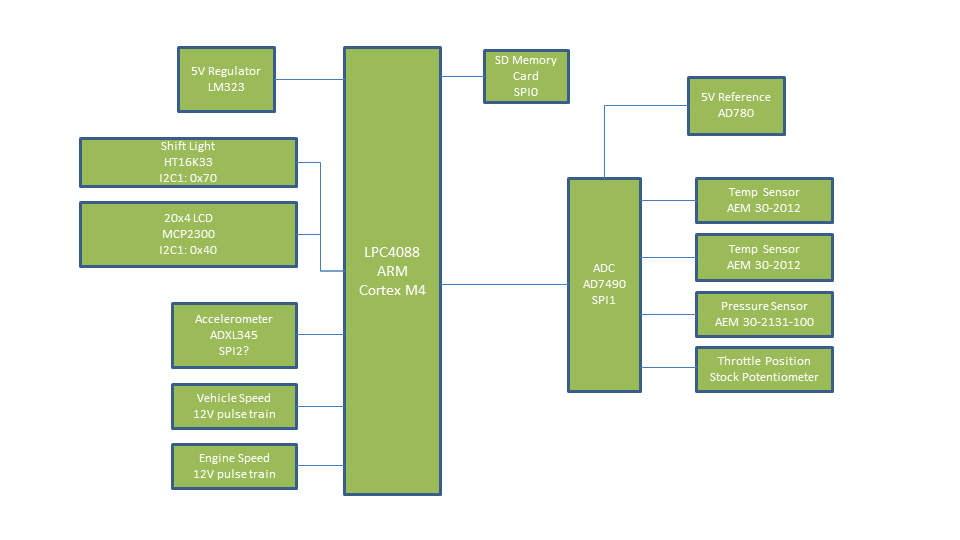

I went around in circles for a few weeks trying to figure out the best way to deal with the main unit. My initial thought was to spin an entirely new PCB to house the LPC4088 Quickstart board, SDcard interface, accelerometer, ADCs, buffer opamps, etc, etc. Basically it would replace the LPC4088 QSB Base Board and add the additional components I needed. Nice and clean.

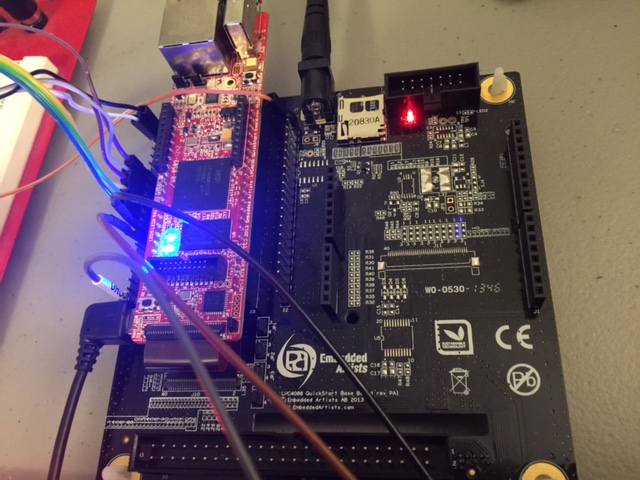

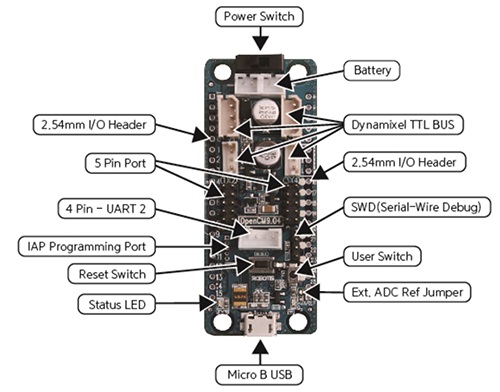

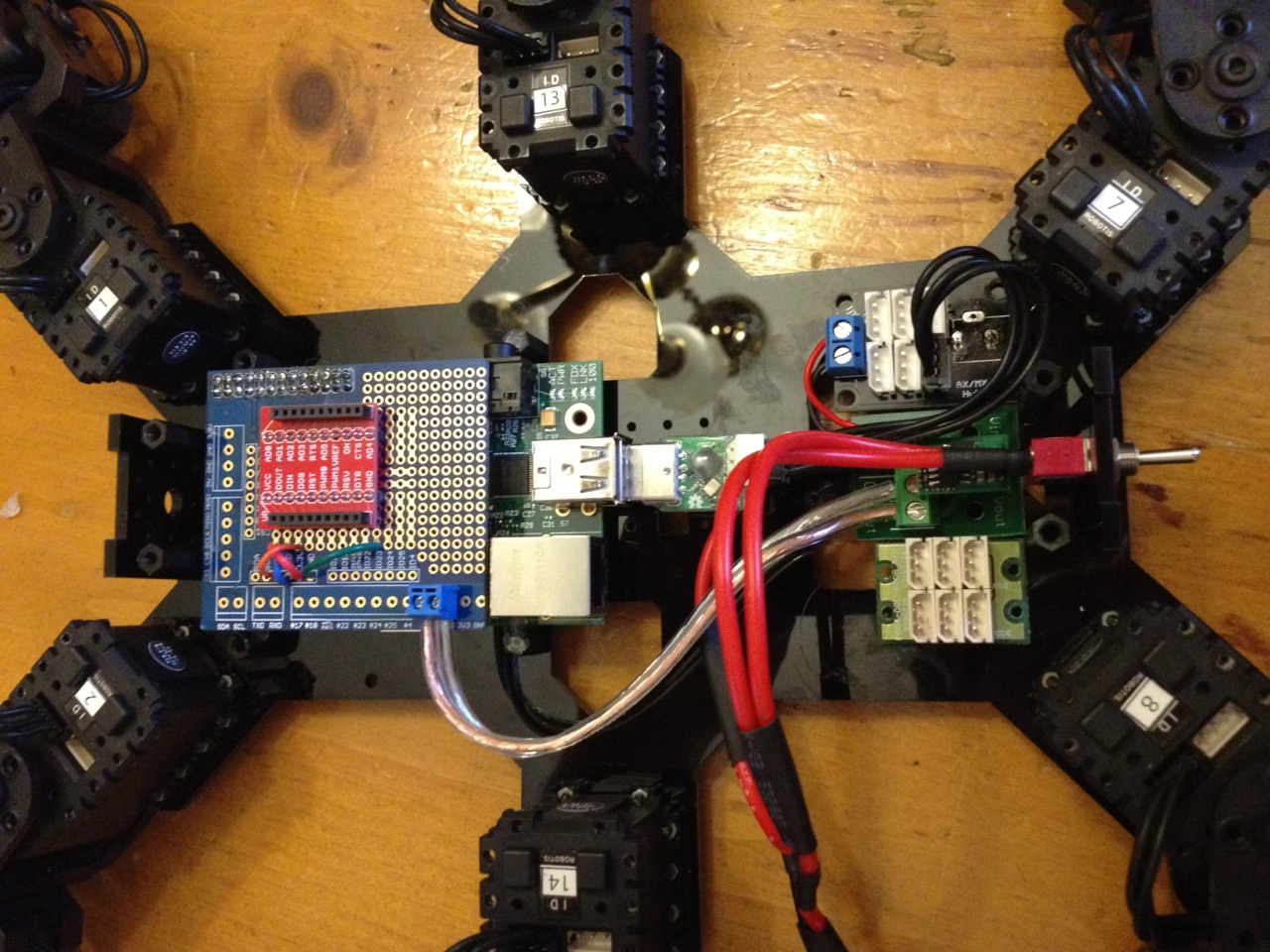

After thinking a bit, however, I came to the conclusion that this would be pretty redundant, entail a much more complicated design effort, and cost more to build. I might as well use what’s been done for me and simply add what I need. Fortunately, the Base Board has an Arduino shield interface. I can just build a shield! It will plug into the empty shield header interface shown here:

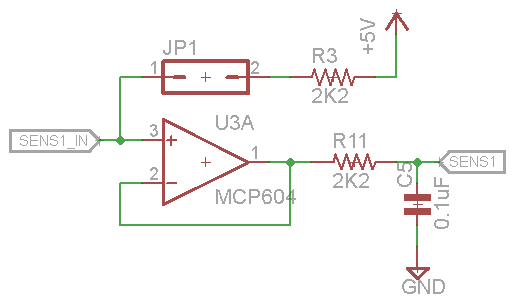

The other benefit of this reduced scope is that I can actually get the design done and built in a timely manner. I decided on using a Microchip 8-channel MP3208 12-bit ADC. This will cover 8 channels of 0-5V analog input, plenty for my logger. I’m using MCP604 opamps and basic RC filters for input buffering/filtering.

Here’s an example of one of the analog input circuits. It has an optional 5V pullup via jumper, buffer, and antialiasing filter.

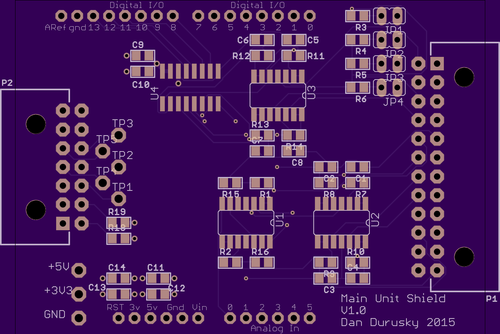

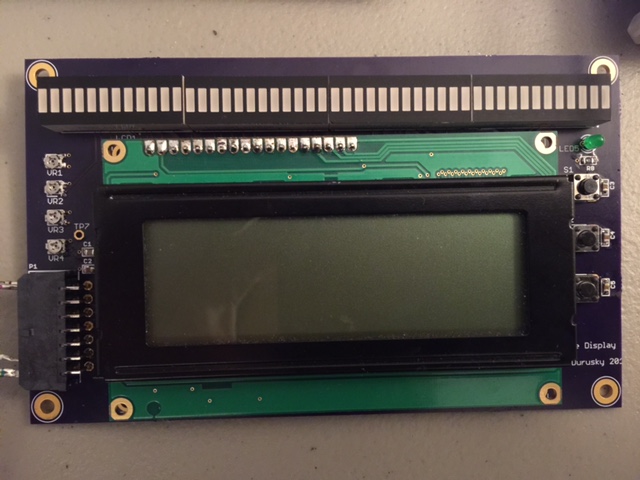

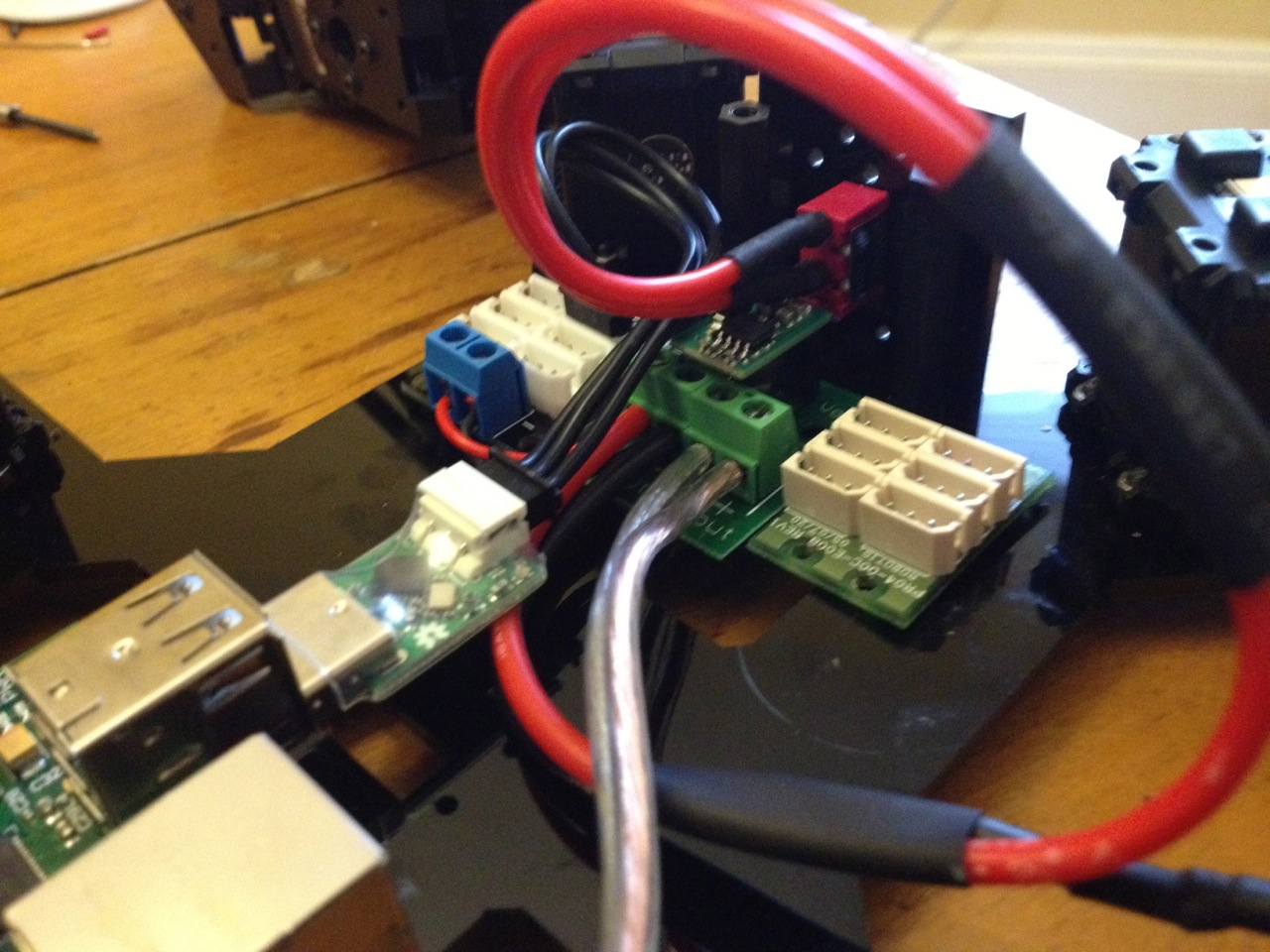

The other main purpose of the shield is two connectors. One for all my sensors to connect to as inputs and the other to connect to the Remote Display.

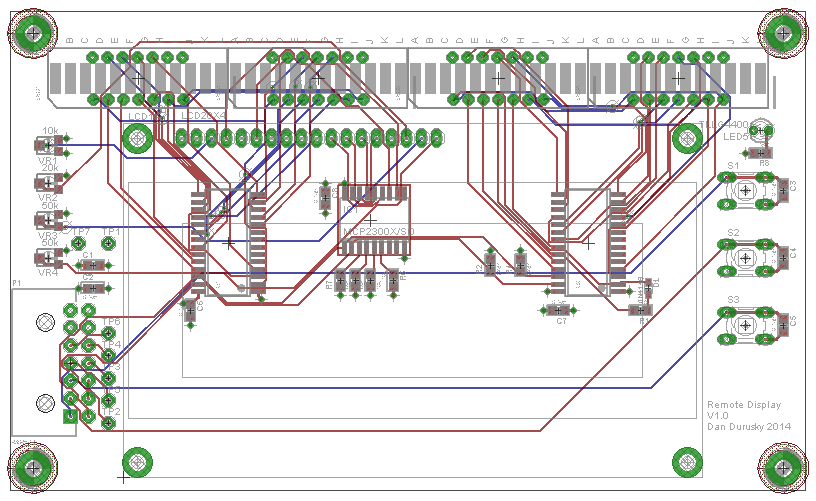

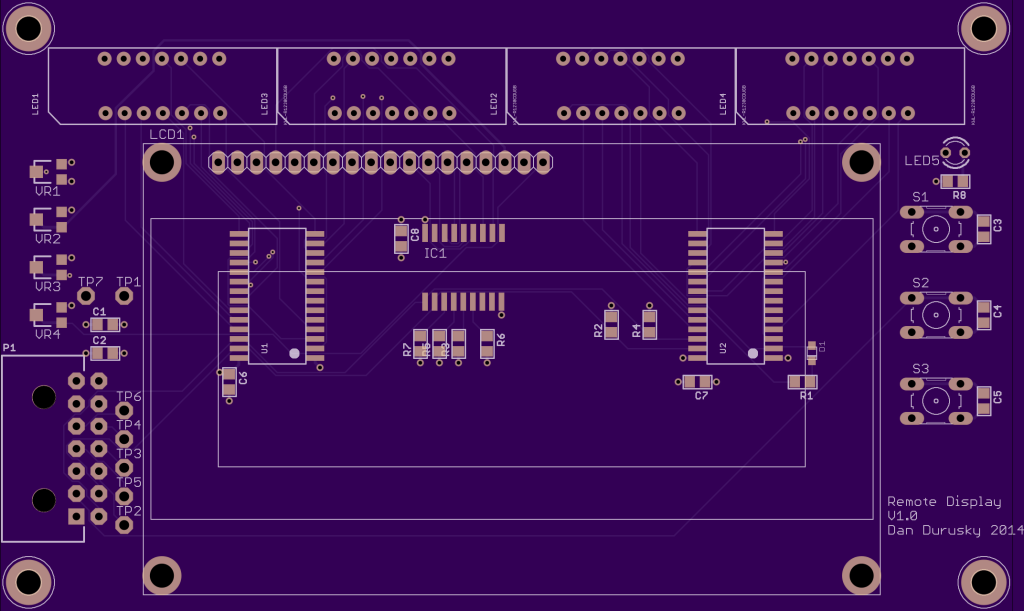

The board looks like this:

I just placed the order today so the PCBs should be here in a couple weeks. In the mean time i need to gather up the BOM and order the parts.

In the meantime I plan to focus on the software a bit and get that decent shape. More to come!