Last fall I was prepping for the install of a bolt-in 4-point roll bar when i noticed a crack under my back seats…

That couldn’t be good so I had an excellent local race shop, Vintage Sports & Restoration, take a look. And they found a cracked subframe.

This is a fairly uncommon failure on an E36. Typically it is the stubframe *mounts*, which are a part of the unibody of the car, that crack. My mounts were fine, but it was this ear of the subframe itself that cracked.

The shop also noticed that the previous owner had installed solid aluminum differential mounts, but kept the original rubber subframe mounts in place. With no isolation between the diff and the subframe, all that driveline energy was being applied to the rubber bushings. They quickly died and eventually fatigued the subframe and it cracked. At the point, the driveline energy was being coupled to the unibody asymmetrically through three instead of the four mounting points and that probably caused the stress crack under the seats. So the moral of the story is to understand how bushings/mounts work and make sure they’re being used as a system.

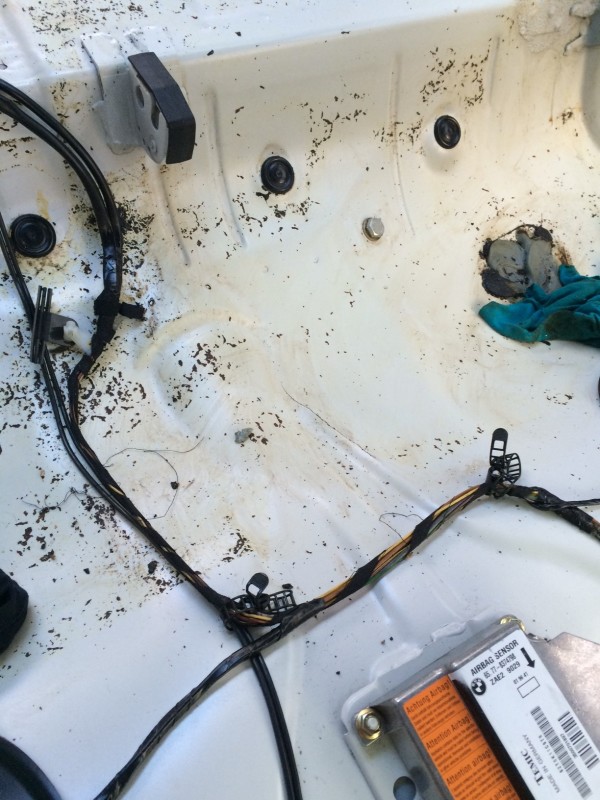

So VSR installed a new freshly painted subframe with 75D mounts. Being the foundation of the rear suspension, we wanted a firm interface here. We opted against going full aluminum because we do want to reduce some of the high frequency energy that can be rough on a street driven car both in sound and metal fatigue.

We then used 95A poly diff mounts so that there is some give to the driveline, but it it still much stiffer than stock to sharpen the response a bit.

If that wasn’t enough, the shop said my diff was making a lot of noise and the left side output shaft bearing was shot. That snow balled into a brand new 3.46 2-clutch, 40%, 45/45 LSD from Dan at diffsonline.com. Dan’s work is top notch and his diffs are very common among the club racers. I rebuilt the LSD in my old E30, but I decided to let the pros handle this one. Since the car is still driven to and from tracks as far a way as 6-9 hrs, I chose the 3.46. The more racey 3.64 is perfect for a trailered race car but it revs too high for comfortable highway driving.

So as of yesterday the car is home again. Here’s a final rundown of what’s new:

- 4-pt bolt-in roll bar with custom harness bar height (I’m tall)

- Repaired crack under rear seats

- Refurbished subframe w/ AKG 75D bushings

- Rebuilt 3.46 LSD from diffsonline.com. 95A bushings

Next up is:

- Install seats (Cobra Suzukas w/ VAC hardware)

- Install harnesses (Schroth ProFi 6-pts)

- Install new valve cover gasket (I have quite a leak now) and spark plugs

- Install oil temp, water temp, oil pressure sensors (for digital dashboard)

- Break in new diff!